When it comes to simple consumables like car brake pads, you might wonder, "Is the warning light on?!" "Is it time for a replacement?!" "Is there a noise?!" These parts are easy to replace, but imported cars can be particularly tricky.

Why is that?! The most common issue when replacing brake pads is noise, along with the cost of performance compared to original parts. Additionally, there may be extra work needed due to disk wear and tear.

You have to consider a lot when working on these components.

So, when dealing with imported cars, it's essential to listen carefully during consultations or visits for repairs and discuss what needs to be done!

"They'll do a good job, right?!" Of course, we will, but satisfaction varies from person to person, so it's best to communicate!

Today, we will work on a BMW imported vehicle.

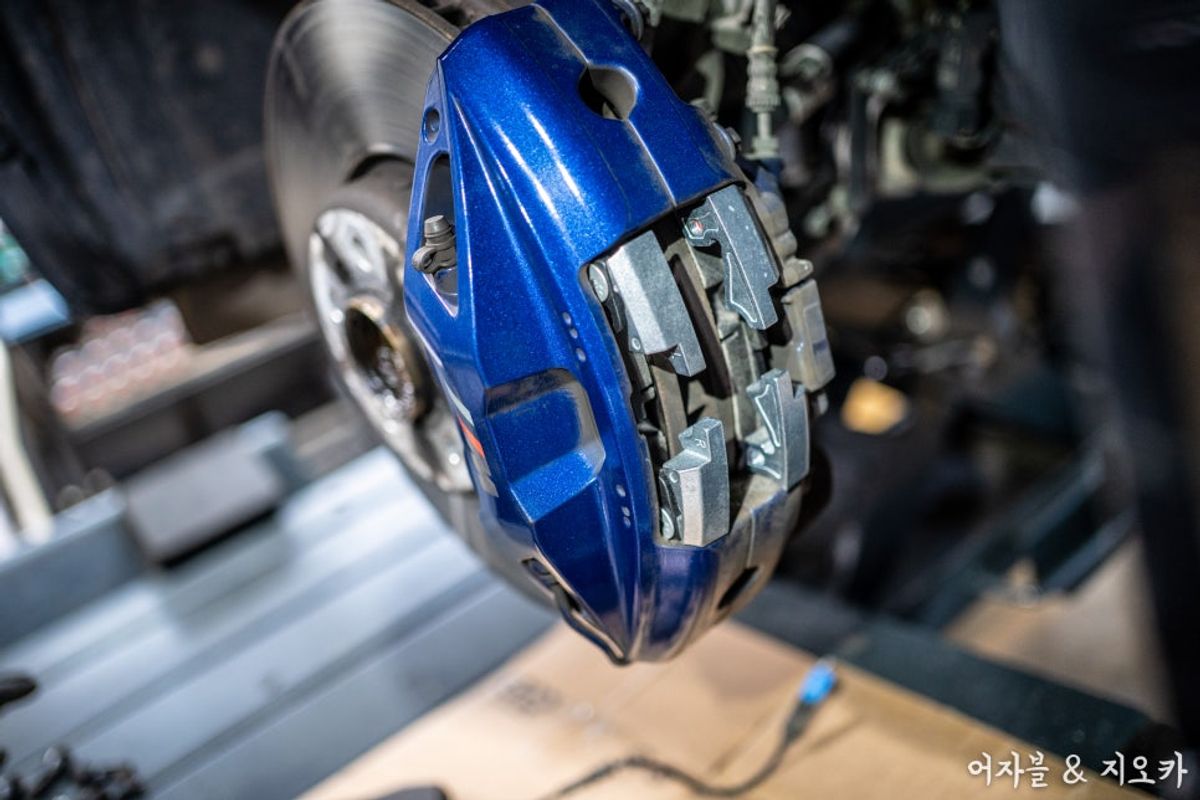

The model is an X3 with an M Sport package brake system. You can consider it as BMW's high-performance version.

Previously, we replaced the rear brake pads, and the customer was satisfied, so they requested the front pads as well.

We will use low-noise, low-dust ceramic brake pads, which come as a set with sensors. The disk condition is somewhat ambiguous at 100,000 kilometers, but the wear isn't as high as expected, so we decided to replace only the pads.

The advantage of low-noise ceramic pads is that they produce less dust!

After we replaced the rear pads, the wheels look clean, right?!

The front brakes, however, show a high level of contamination from dust.

The dust comes from the brake material, which generates friction and causes dust from the pads and disks to scatter.

The ceramic material reduces this dust output compared to original parts, and it also minimizes noise.

* While low-noise pads exist, none are 100% silent. Each vehicle's driving environment and braking methods differ, so some noise may still occur! If I could find a completely silent pad, I would patent it!

So, while it may seem ideal to use ceramic pads for their low noise and minimal dust, the downside is that they can have slightly lower braking power compared to original parts.

When I say braking power is lower, you might think, "Does that mean my car won't stop well?!" But it's not that drastic; if original parts are rated at 100, ceramic pads would be around 80.

The owner of this vehicle has chosen ceramic pads after trying the rear ones!

Let's get this job done neatly!

The front of the BMW X3 has a 4-piston setup, which differs from standard pads that typically break with pins!

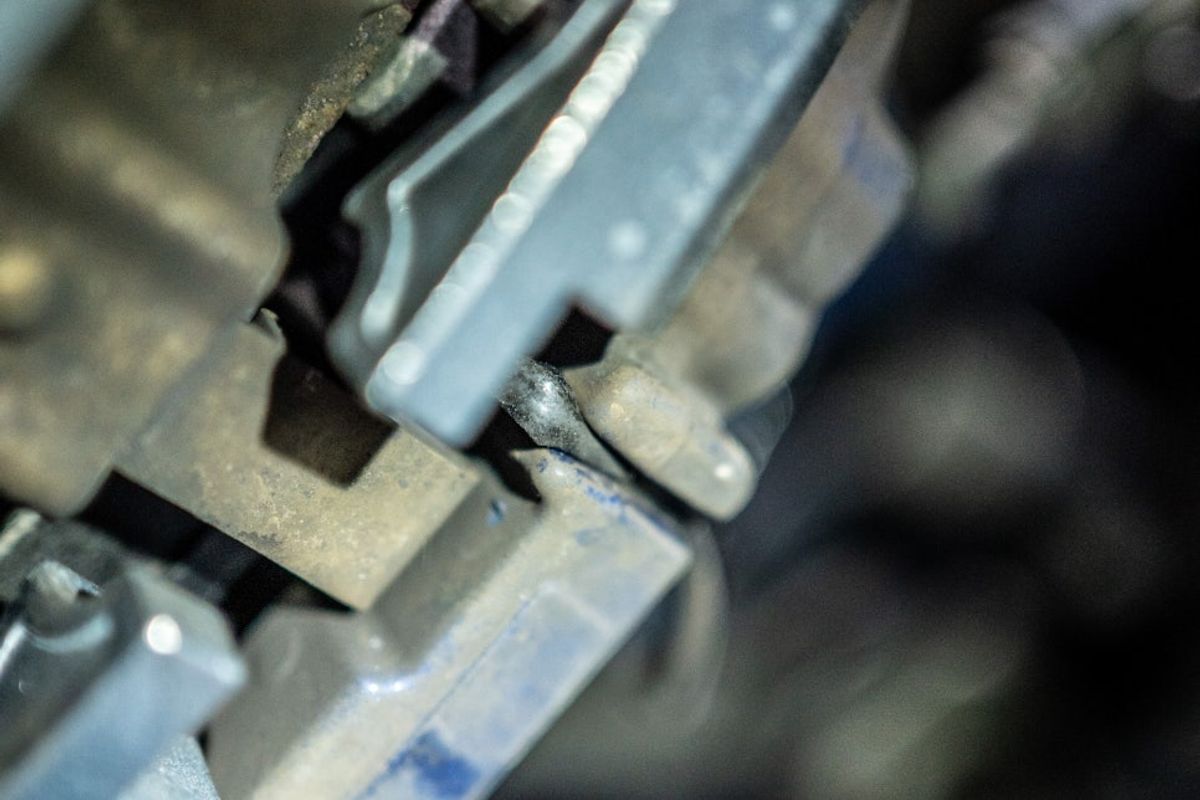

Here, a lot of dust accumulates, and if we don't clean it, it can harden and cause problems with pad return or noise later on.

We will remove as much of the existing dust as possible.

We install the new pads by placing them on top of the caliper.

We secure them with the fixed pins.

Finally, we install the new sensor, and the job is complete.

Compared to domestic cars, imported vehicles often require additional steps, so the parts and replacement methods vary slightly by model, brand, and brake specifications.

Additionally, BMW brake pads trigger a warning light when they wear out, right?!

You need to reset, or in other words, initialize it as well!

As we transition from winter to hot summer, let's reset the tire pressure as well.

We install the wheels and tires using a torque wrench.

We conduct a simple test drive to ensure everything is functioning well.

We then release the vehicle.

This task is common, but it’s essential to double-check everything after completion!

There are many variables, and customer satisfaction can differ, making brake pad replacements a meticulous task.

In conclusion, if you decide to go with aftermarket OEM parts, consider this approach!

Try it out!

If you prefer original specifications, we can set that up for you too, so please consult with us!

Thank you.